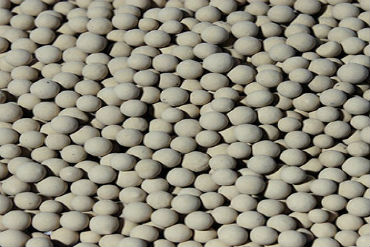

The carbon molecular sieve (CMS) is a new nonpolar absorbent with adsorbing oxygen molecule to get nitrogen-enriched air at normal temperature. The ability of separating the air decided by propagation rate, adsorptive attraction or the same effect of each gas in carbon molecular sieve pore. The carbon molecular sieve is widely applied in petroleum chemical industry, the heat treatment of metal, the electronic manufacture and food preservation industries.

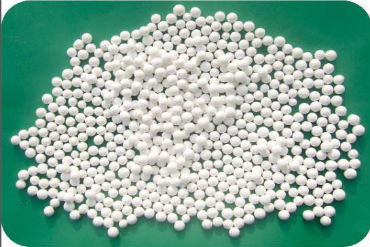

Activated Alumina Made by de-hydroxylating aluminum hydroxide in a proprietary way to generate a high-surface porous structure, GLOBAL ALUMINOXITE range of activated alumina (Al2O3) is an amorphous compound that offers excellent adsorption characteristics for removal of a wide variety of contaminants. It has a surface area of up to 350 m2/g and is used as a desiccant and a filter to remove arsenic, fluoride and selenium from potable water.

Carbon for a wide range of industrial applications, including air, gas and water purification.Heightened environmental awareness and the enactment of strict emissions guidelines have led to the development of new several new applications. Our Activated Carbon is also being used in other industries, including Oil absorption and petrochemical processes. Our carbon is also being used to an increasing extent in the treatment of water, including drinking water, ground-water, service waster and waste water. Its primary role in this context is to adsorb dissolved organic impurities and to eliminate substances affecting odor, taste and color in halogenized hydrocarbons and other organic pollutants. Yet another broad field of application for activated carbon is the treatment, purification and decolourisation of liquids, which is of particular importance in the pharmaceuticals, food, beverage and other allied industries.

Product description: We are extremely engaged in providing Palladium Catalyst for Nitrogen De-oxo. Due to extremely demand, we provide these products in diverse forms that meet on customers demand. Palladium catalyst for PSA Nitrogen Generator De-Oxo: Genuine de-oxo palladium catalyst for your nitrogen generator Guaranteed performance Ready stock Immediate delivery Irrespective of which make Nitrogen generator you have, we can supply you the correct palladium catalyst

What is Palladium Catalyst?

For production of high purity gases such as Nitrogen, requires use of high activity catalysts for the removal of impurities. Oxygen is a major impurity in inert or reactive gases and therefore reducing its concentration is a subject of continual interest. The goal of using palladium catalyst is the removal of oxygen from nitrogen, thereby delivering high quality inert gas with ppm levels of Oxygen remaining. Hydrogen levels can be modulated depending on customer's process requirement for HNX (Hydrogen-Nitrogen mixture.

An active copper chromite catalyst which includes barium in its structure can be prepared from a solution containing barium nitrate, copper(II) nitrate .the LTS catalyst is a copper-based catalyst. The order proceeds from high to low temperature due to the susceptibility of the copper catalyst to poisoning. The compound is useful as a catalyst, in electroplating copper, and as a reagent in the preparation of nitriles. Copper cyanide is a coordination polymer

Nickel is slowly oxidized by air at room temperature and is considered corrosion-resistant. Historically, it has been used for plating iron and brass, coating chemistry equipment, and manufacturing certain alloys that retain a high silvery polish, such as German silver. About 9% of world nickel production is still used for corrosion-resistant nickel plating. Nickel-plated objects sometimes provoke nickel allergy. Nickel has been widely used in coins, though its rising price has led to some replacement with cheaper metals in recent years.

A sieve, or sifter, is a device for separating wanted elements from unwanted material or for characterizing the particle size distribution of a sample, typically using a woven screen such as a mesh or net or metal.[1] The word "sift" derives from "sieve". In cooking, a sifter is used to separate and break up clumps in dry ingredients such as flour, as well as to aerate and combine them. A strainer is a form of sieve used to separate solids from liquid.