Hydrogen Gas Plants

TECHNICAL DESCRIPTION

01 FLOW RANGE

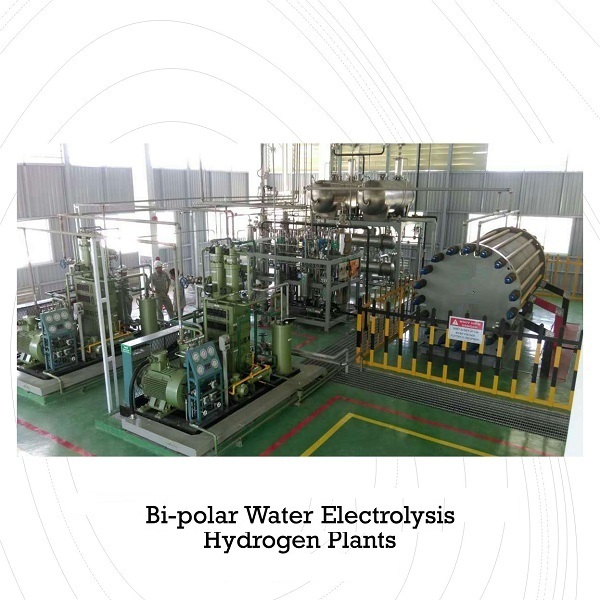

We also offer custom designed bi-polar water electrolysis units manufactured by MEC. We offer flow range from 5 to 500 nm3/hr in a single train.

02 HYDROGEN PURITY

Our systems offer purities ranging from 99.9% Hydrogen to 99.9998% Hydrogen, with balance impurities being water vapour, trace nitrogen and trace oxygen. Customers can optionally purchase online gas purity measurement instruments.

03 DEW POINT

Our Hydrogen generators deliver very dry gas, with dew point as low as (-) 65°C. We also offer measuring instruments for online detection of gas dryness.

04 PRESSURE

Hydrogen gas is delivered from our systems, typically at 15 kg/cm2g without the need of a booster compressor. This pressure satisfies the requirement of the majority of our customers. We can also offer and integrate a booster if the customer requires Hydrogen gas at a higher pressure.MEC INDUSTRIAL BI-POLER HYDROGEN GENERATOR

HOW IT WORKS

2H2O = 2H2 + O2

Demineralized (or Deionized) water is used as feed. The water passes through the Electrolyzer cell stack where DC current is applied causing water to split into Oxygen and Hydrogen. Oxygen is safely vented, whereas the Hydrogen is delivered as the product gas. Hydrogen is taken to a dryer where the excess moisture is removed. Hydrogen gas is delivered to the customer process at high pressure directly from our system. For customers requiring cylinder filling option, we supply triple-diaphragm hydrogen booster and cylinder filling stations..SAFETY

MEC hydrogen generators, operating at Membrane technology work on the principle of differential pressure. Hydrogen is produced at 15 kg/cm2g pressure or higher and Oxygen is typically below 2 kg/cm2g. This high differential pressure will not permit Oxygen to entrain the Hydrogen stream and thereby giving inherent safety. In the case of the Hydrogen leak, the onboard leak detectors will sense very low levels of Hydrogen and shut down the system in case of abnormality.

MEC bi-polar water electrolysis Hydrogen generators have advanced monitoring systems ensuring plant operational safety. The systems safely depressurize and shut down in the case of abnormal operation.

MEC INDUSTRIAL Hydrogen Gas Plants

Hydrogen Generator (Water Electrolysis)

| Product | Hydrogen Generator |

| Applications | - Steel And Metal Processing

- Float Glass - Edible Oils and Oleo Chemicals - Power Consumption - Electronics and Semi Conductors - Meteorology Applications - New Energy Sources, Solar Application |

| Process Description | Hydrogen from water electrolysis is an established technology. Hydrogen flows from hydrogen electrolyser to gas lye treater and Hydrogen Purifier unit. Fully automatic control is achieved and is available for connection with DCS systems for monitoring.These Environment friendly Hydrogen Gas Generation plants offer great convenience to the customers for installation, easy operations and maintenance. |

Hydrogen Gas Plants (Steam Reforming)

| Product | Hydrogen Gas |

| Applications | - Chemicals

- Electronics and Semi Conductors - Steel and Metal processing - Power Generation |

| Process Description | Steam Reformer, natural gas is preheated and desulphurized before mixing with steam. Once mixed with the steam in the desired ratio, the natural gas undergoes catalytic reformation in Reformer to produce Carbon monoxide, Carbon dioxide and Hydrogen. The mixture then undergoes shift reaction to convert the CO into CO2. The mixture from here gets transferred to the PSA section to adsorb CO, CO2, CH4 and N2 (from purging) and produces pure Hydrogen. The desorbed gas from PSA can be used as fuel for combustion in the Reformer. |

Hydrogen Plants (Methanol Cracking)

| Product | Hydrogen Gas |

| Applications | - Chemicals

- Oleochemicals - Steel and Metal processing - Power Generation |

| Process Description | Methanol and Demineralised Water is mixed, preheated, evaporated and superheated. The mixed superheated gasses the undergo catalytic cracking process and shifting of Carbon Monoxide to form a mixture of Hydrogen, Carbon dioxide and residues of Carbon Monoxide in small quantities. The mixture of gasses is transferred to the PSA section to obtain pure Hydrogen. |