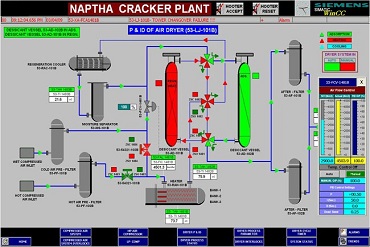

MECBURG ENGINEERING & CONSULTANCY SCADA systems offer maximum functionality and a user-friendly user interface. With our configurable and scalable systems, you have the advantage of absolute openness to both the office environment and to production. An integrated process database and Plant Intelligence, for example, ensure transparency in production. Numerous options and add-ons extend and expand the scope of performance.

Efficiency in terms of engineering & operations control

Efficient engineering, integrated diagnostics functions and flexible production analysis ensure reduced time-to market as well as minimised plant downtimes. SCADA provides a reliable decision basis for optimisations and thus supports increased productivity coupled with reduced costs.

Innovative solutions

Thanks to innovative technology, all important information is consistently available – rapidly, flexibly and safely. SIMATIC WinCC thus eases your production’s intuitive operation and monitoring – also remotely.

Easy scalability

SIMATIC WinCC facilitates your plant’s easy functional or sector-specific expansion or modernization. Benefit from redundancy concepts for increased availability or opt for central plant information archiving and analysis.

Variety of systems available

TES can provide you with a range of SCADA systems to best suit your requirements including Siemens WinCC, Rockwell Automation, Wonderware and Iconics.

MECBURG ENGINEERING & CONSULTANCY source a range of leading Programmable Logic Controllers (PLCs), to control industrial processes or machines. They provide advanced functions, including analogue monitoring, control and high speed motion control as well as share data over communication networks.

Typical hardware configurations consist of the following devices;

- Single PLC (typically hot standby) controlling large plant with external IO stations over typically profibus/Ethernet network. Large distances incorporate fibre links to ensure rapid data transfer.

- Multiple PLC’s linked together over Ethernet networks controlling several areas of a large plant. System can utilise remote IO stations over communications networks.

- Multiple HMI’s can be provided displaying all signals centrally at each station.

- Whatever the requirement TES can provide a customised solution to meet your exact needs.