Desiccant Dryer

Compressed Air Systems should be designed for just the right quality of air at the most economical costs. Mec has a wide range of dryers for all your needs, for general plant and instrumentation air.

If the application requires extra dry air and PDP below -20°C, the Mec has a large range of adsorption dryers for the job-heatless regenerated and energy-less.

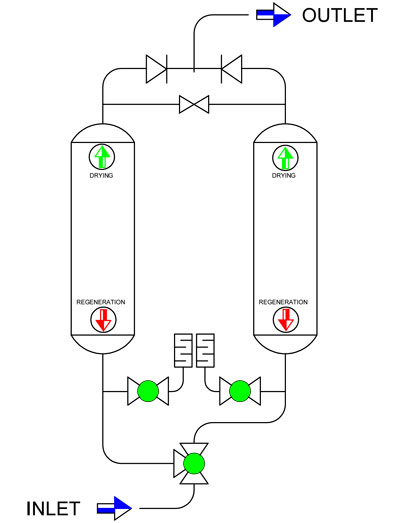

Desiccant Dryers, heatless type, use 10 to 15% purge air for regeneration of desiccant i.e. 10 to 15% of compressor power (HP) is being used as energy operating costs for drying thereby increasing the capital costs in installing extra capacity of compressor. They contain two pressure vessels or towers, each containing a quantity of desiccant. One tower dries the air, while the other is being reactivated.

The 'heatless' principle of regeneration is based on the physical property of the desiccant, given as Delsorb as one of its kind in Asia and approved by all major consultants, which liberates the adsorbed water vapour, if air with a low water vapour pressure is passed through it.

How does it work?

Rust and pipe scale deposits in steel pipes, increased resistance to flow, malfunctioning of pressure control equipment, corrosion in electromagnetic valves, solidification of media in pneumatic conveying systems, bubbling or orange peel effect in paint spraying are all consequences of water in the compressed air system. It not only endangers your delivery dates but quickly soaks up profits.

Air drawn into the compressor will, depending upon the relative humidity, contain 60% to 80% of water vapour. Under compression, some of this converts to water and can be removed by line filters. However, as the temperature drops, water vapour will re-appear as condensation.

Water vapour can only be economically removed by two methods: one is by cooling the air; the other more efficient method is by adsorption. The Mec range comprises of both Refrigeration Dryers and Adsorption Dryers. Refrigeration dryers are used for application requiring air with pressure dewpoints to 4°C to 6°C. Adsorption Dryers provide a much lower pressure dewpoint, from -20 Deg.C to -40 Deg.C, at a relative compressed air humidity of only 0.1%.

These are available as Heatless, Heat regenerated (Reduced Purge Air), Heat regenerated and Energyless.

Key Features

- Available in 15 standard models

- Atmosperic dew point achievable till (-) 60°C

- Electronic controls/solid state timers for automatic and reliable operation

- Low power consumption

- Equipped with muffler on purge air outlet to reduce noise level

- Specially graded desiccant delsorb 10 & delsorb 21 for optimum performance and long life Purge valve.